What is the difference between the rust removal effects of steel wire brushes, copper wire brushes, and nylon brushes?

2025-07-16

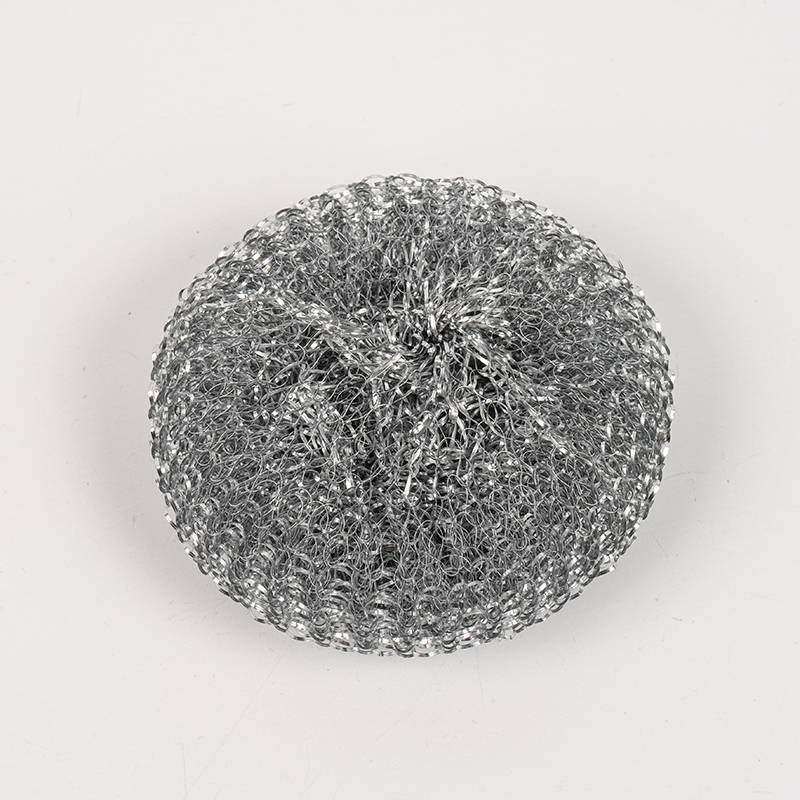

As a powerful Rust Cleaning Tool Scourer, the steel wire brush can scrape violently with its hard steel brush wire, and has a significant effect on thick rust and stubborn oxide layers. It can quickly peel off large pieces of rust, but the impact force is too strong, which can easily leave obvious scratches on the surface of the substrate, especially not suitable for fine-machined surfaces or softer metals. This type of rust removal tool cleaning brush is more suitable for steel structures, large castings, or rough surface treatments with low requirements, and is the first choice for tackling heavy rust.

The copper wire brush provides a more gentle solution. Its brush wire is flexible and not easy to spark, and it has good removal ability for moderate rust, while protecting the substrate from scratches to the greatest extent. It performs well when handling precision parts, bearings, non-ferrous metals (such as copper, aluminum), or workpieces that need to retain the original surface (such as antique restoration), and can efficiently remove floating rust and light oxide layers without damaging the body. This Rust Cleaning Tool Scourer has found the best point in balancing effect and protection.

The rust removal mechanism of nylon brushes is more inclined to surface cleaning and polishing. Its brush wire has the lowest hardness and relies on friction with cleaning agents (such as rust removal liquid) to remove light floating rust, oil and dust, and basically does not damage any substrate. It is often used for fine equipment, coating surface pretreatment, or as a fine cleaning tool after rough rust removal with steel wire brushes and copper wire brushes, which can provide a smooth surface state. Nylon brushes are often used in conjunction with sandblasting and chemical rust removal as the final cleaning step to ensure that the workpiece is completely free of residue.